44 WCF with IMR 4227 or RL-7?

Forum rules

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

44 WCF with IMR 4227 or RL-7?

Does anybody have load data for IMR 4227 or RL-7 with a 200 grain bullet in an original Winchester 73. I got some 200 grain bullets with the crimp groove in the wrong place and I would like to use a case full of powder to support the bullet. Any other powder suggestions might be helpful but I have these two.

My "HB" (Hunting Buddy) She's a good cook too!

-

Lefty Dude

- Senior Levergunner

- Posts: 1459

- Joined: Wed Feb 06, 2008 6:31 pm

- Location: Arizona Territory

Re: 44 WCF with IMR 4227 or RL-7?

73's do not have a strong action. The only way you are going to get a case full is with Black Powder. Do not use loads for the 92 and shoot them in your 73. The 73 action was designed for Black Powder, the 92 Smokless. Any smokless powder that fills the 44WCF case will not be safe for your 73.

If you do work up top loads, do it with extreme caution.

In the day, Winchester & Remington made smokless loads for the 73 and the ones that were hotter was for the 92 only.

I shoot a 73 & 92 in 44WCF, I have no loads that will not shoot in both Rifles. I do not want to take the chance of wrecking my 73.

There are some stiff full loads that push a 200 gr jacketed bullet in a 92 at over 2000fps. And guaranteed to take apart a 73 with one shot.

If you do work up top loads, do it with extreme caution.

In the day, Winchester & Remington made smokless loads for the 73 and the ones that were hotter was for the 92 only.

I shoot a 73 & 92 in 44WCF, I have no loads that will not shoot in both Rifles. I do not want to take the chance of wrecking my 73.

There are some stiff full loads that push a 200 gr jacketed bullet in a 92 at over 2000fps. And guaranteed to take apart a 73 with one shot.

SASS# 51223

Arizona Cowboy Shooter's Assoc.

Cowtown Cowboy Shooter's Assoc.

Uberti 73/44-40 carbine, Rossi 92/44-40,

Marlin 94CB/44 24" Limited, Winchester 94/30-30

Arizona Cowboy Shooter's Assoc.

Cowtown Cowboy Shooter's Assoc.

Uberti 73/44-40 carbine, Rossi 92/44-40,

Marlin 94CB/44 24" Limited, Winchester 94/30-30

- Carlsen Highway

- Levergunner 2.0

- Posts: 498

- Joined: Tue May 27, 2008 8:23 am

- Location: Dunedin, New Zealand

Re: 44 WCF with IMR 4227 or RL-7?

We are loading 24 grains of 4227 in .44/40 and it doesnt fill the case. This is suppossed to be a top load and not for the '73 I suppose.

A person who carries a cat home by the tail, will receive information that will always be useful to them.

Mark Twain

Mark Twain

Re: 44 WCF with IMR 4227 or RL-7?

I am well aware of the strength issues which is why I stated the rifle is a 73. I would like to see chronographed data. I have different sources here that show wildly different velocities for 4227. I also have XMP 5744 and IMR 4759. Maybe they are candidates.

My "HB" (Hunting Buddy) She's a good cook too!

-

Lefty Dude

- Senior Levergunner

- Posts: 1459

- Joined: Wed Feb 06, 2008 6:31 pm

- Location: Arizona Territory

Re: 44 WCF with IMR 4227 or RL-7?

I would try SR4759 or 5744. SR4759 was designed by Dupont as a low pressure smokless substitute for BP.Marc wrote:I am well aware of the strength issues which is why I stated the rifle is a 73. I would like to see chronographed data. I have different sources here that show wildly different velocities for 4227. I also have XMP 5744 and IMR 4759. Maybe they are candidates.

Not much data available for low pressure loads for the 44WCF, this cartridge was almost dead 15 years ago. CAS brought it back from the Dead.

I would suggest you contact "Birdshot" at Hodgdon Powder co. 913-362-9455. I do not know his real name, that is his Cowboy allias. Hodgdon bought the rights to Dupont powders & Winchester powders.

Good luck

SASS# 51223

Arizona Cowboy Shooter's Assoc.

Cowtown Cowboy Shooter's Assoc.

Uberti 73/44-40 carbine, Rossi 92/44-40,

Marlin 94CB/44 24" Limited, Winchester 94/30-30

Arizona Cowboy Shooter's Assoc.

Cowtown Cowboy Shooter's Assoc.

Uberti 73/44-40 carbine, Rossi 92/44-40,

Marlin 94CB/44 24" Limited, Winchester 94/30-30

- Old Time Hunter

- Advanced Levergunner

- Posts: 2388

- Joined: Sun Apr 01, 2007 11:18 am

- Location: Wisconsin

Re: 44 WCF with IMR 4227 or RL-7?

8.2 grains of Unique, 200 grain bullet, 24 1/4" barrel = 1196 fps ave in my original '73. Averaged over 50 chrono'd shots with chrono @ 15'.

I am sure that if you hear from Kirk D, he'd have a bunch more info.

I am sure that if you hear from Kirk D, he'd have a bunch more info.

-

Ben_Rumson

- Advanced Levergunner

- Posts: 2569

- Joined: Sat Sep 15, 2007 12:51 pm

Re: 44 WCF with IMR 4227 or RL-7?

Alliant lists 23.5 grains Reloder 7 @ 1290 fps with a 240 grain lead bullet @ 12500 C.U.P. This charge doesn't fill the case but gets the powder very near the bullet base..You should be able to use it with no worries with the 200 grain bullet..It too leaves unburnt powder in the bore.. I get groups in the 1.5 to 2" range at 50yds using the Lyman 429215GV gas check bullet... avg 1255fps out of my circa 1889 Mod.1873 SRC .. I wouldn't recommend getting that mold however because if you crimp in the crimp groove the OAL is about .060" too long to cycle..I crimp at the very edge of the driving band with the Lee FCD..I got it to see if the gas check would improve accuracy because the bore is eroded just in front of the chamber..Seems to be working much better now..10 shots

"IT IS MY OPINION, AND I AM CORRECT SO DON'T ARGUE, THE 99 SAVAGE IS THE FINEST RIFLE EVER MADE IN AMERICA."

WIL TERRY

WIL TERRY

Re: 44 WCF with IMR 4227 or RL-7?

Ben,

Glad to see that you're getting great results with your new bullet.

Marc,

As Ben Rumson stated, Alliant shows a load of 23.5 grs. under a 240 gr. bullet @1,290 f.p.s. and 12,500 c.u.p. which is over 10% below SAMMI MAP for the .44-40.

I have an original '73 Winchester with a 21" barrel. With a lighter 213 gr. bullet I use 25 grs. Rel 7 (capacity load) and the velocity is 1,252 f.p.s. In a friends '73 with a 24" barrel - 1,367 f.p.s. Accuracy has been very good.

I use a lot of H4227 in my '73. 17 grs under a 200 gr. cast bullet gives 1,250 f.p.s. but best results come when the powder is positioned to the back of the case. I do that by raising the muzzle to a 45 degree angle momentarily with the lever about 75% closed. I then close the lever the rest of the way when the rifle is pointed at the target.

Have fun!

w30wcf

Glad to see that you're getting great results with your new bullet.

Marc,

As Ben Rumson stated, Alliant shows a load of 23.5 grs. under a 240 gr. bullet @1,290 f.p.s. and 12,500 c.u.p. which is over 10% below SAMMI MAP for the .44-40.

I have an original '73 Winchester with a 21" barrel. With a lighter 213 gr. bullet I use 25 grs. Rel 7 (capacity load) and the velocity is 1,252 f.p.s. In a friends '73 with a 24" barrel - 1,367 f.p.s. Accuracy has been very good.

I use a lot of H4227 in my '73. 17 grs under a 200 gr. cast bullet gives 1,250 f.p.s. but best results come when the powder is positioned to the back of the case. I do that by raising the muzzle to a 45 degree angle momentarily with the lever about 75% closed. I then close the lever the rest of the way when the rifle is pointed at the target.

Have fun!

w30wcf

aka John Kort

aka Jack Christian SASS 11993 "I can do all things through Christ who strengthens me." Philippians 4:13

aka w44wcf (black powder)

NRA Life member

.22 WCF, .30 WCF, .44 WCF Cartridge Historian

aka Jack Christian SASS 11993 "I can do all things through Christ who strengthens me." Philippians 4:13

aka w44wcf (black powder)

NRA Life member

.22 WCF, .30 WCF, .44 WCF Cartridge Historian

Re: 44 WCF with IMR 4227 or RL-7?

Thank you gentlemen! I also found a copy of a page from Handloader that a friend gave me some time ago. It shows 18 grains 4227 with a Hornady 200 JHP for 1230 FPS and with a Lyman 42798 for 1171 FPS. This will give me something to work with.

My "HB" (Hunting Buddy) She's a good cook too!

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

I know this is another old topic but I wanted to add some information. The below is my results and I could be wrong....use at your own risk.

It has been said that Dupont #2 had a similar burn rate as IMR-4227. It has been said that SR80 and Sharpshooter had a similar burn rate as today's 2400.

Notwithstanding the information above........

On the back of the SR80 can I have on hand, it states that 13.7gr is to be used with a 200gr lead bullet to achieve 1,300fps. On a Dupont SR80 load data sheet maybe around WWII...shows 14gr with a 200gr M.C. (JSP) bullet for 1,299fps and 18gr with a 200gr M.C. (JSP) for 1,625fps. I assume the later to be a High Velocity load not to be used in the Winchester 73' or revolvers.

In my testings I feel confident that early black powder loads were closer to 12,500psi rather than 11,000psi in certain semi-balloonhead cases. 11,000psi would be directly equivalent to 13,000cup in SAAMI, not established until the 1960's testings. Early Winchester cartridges used Dupont #2 (Similar burn rate as today's IMR-4227 BUT 4227 IS NOT a bulk powder) which Winchester warned their Dupont #2 loads not to be used in Revolvers but okay for the 73'. IMR-4227 is perfectly safe for all firearms chambered for the 44-40 if modern published data is used. Dupont was replaced by Sharpshooter and SR80 which was developed to replace black powder to be used in all black powder firearms chambered for the 44-40. Ironically these newer powders are all magnum powders.

My testing are divided into two sections, normal velocities that replicate early factory loads and High Velocity, that replicate early High Pressure loads only to be used in the Winchester 92, Marlin 94 type rifles.

Remember Winchester's smaller diameter JSP bullets produce less pressures than any .429 bullet/.429 bores. My 12,500psi BP/BH case loads would probably be higher in older smaller diameter bore rifles.

Using IMR-4227 (have yet to tests 2400 loads), my results follow......

SAAMI MAX 11,000psi/13,000cup

20" MGM custom barrel

10 shots each load

17gr with 200gr Lyman 427098 (.429), 1,127fps @ 9,389psi

19gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,296fps @ 10,643psi

19.5r with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,296fps @ 11,430psi

20gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,357fps @ 12,238psi

22gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,514fps @ 14,541psi

25gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,665fps @ 17,915psi

22gr with 200gr Winchester JSP (.426), 1,386fps @ 12,035psi

25.5gr with 200gr Winchester JSP, 1,735fps @ 19,652psi...this could exceed Winchester's published 22,000cup High Velocity loads. My guess is 18,000psi might be closer to 22,000cup.

26gr with 200gr lead "Magma" (Oregon Trail Laser Cast), 1,733fps @20,913psi...well beyond 22,000cup is my guess!!!

https://curtisshawk21.wixsite.com/44cen ... ss-powders

https://curtisshawk21.wixsite.com/44cen ... re-testing

It has been said that Dupont #2 had a similar burn rate as IMR-4227. It has been said that SR80 and Sharpshooter had a similar burn rate as today's 2400.

Notwithstanding the information above........

On the back of the SR80 can I have on hand, it states that 13.7gr is to be used with a 200gr lead bullet to achieve 1,300fps. On a Dupont SR80 load data sheet maybe around WWII...shows 14gr with a 200gr M.C. (JSP) bullet for 1,299fps and 18gr with a 200gr M.C. (JSP) for 1,625fps. I assume the later to be a High Velocity load not to be used in the Winchester 73' or revolvers.

In my testings I feel confident that early black powder loads were closer to 12,500psi rather than 11,000psi in certain semi-balloonhead cases. 11,000psi would be directly equivalent to 13,000cup in SAAMI, not established until the 1960's testings. Early Winchester cartridges used Dupont #2 (Similar burn rate as today's IMR-4227 BUT 4227 IS NOT a bulk powder) which Winchester warned their Dupont #2 loads not to be used in Revolvers but okay for the 73'. IMR-4227 is perfectly safe for all firearms chambered for the 44-40 if modern published data is used. Dupont was replaced by Sharpshooter and SR80 which was developed to replace black powder to be used in all black powder firearms chambered for the 44-40. Ironically these newer powders are all magnum powders.

My testing are divided into two sections, normal velocities that replicate early factory loads and High Velocity, that replicate early High Pressure loads only to be used in the Winchester 92, Marlin 94 type rifles.

Remember Winchester's smaller diameter JSP bullets produce less pressures than any .429 bullet/.429 bores. My 12,500psi BP/BH case loads would probably be higher in older smaller diameter bore rifles.

Using IMR-4227 (have yet to tests 2400 loads), my results follow......

SAAMI MAX 11,000psi/13,000cup

20" MGM custom barrel

10 shots each load

17gr with 200gr Lyman 427098 (.429), 1,127fps @ 9,389psi

19gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,296fps @ 10,643psi

19.5r with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,296fps @ 11,430psi

20gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,357fps @ 12,238psi

22gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,514fps @ 14,541psi

25gr with 200gr lead "Magma" (Oregon Trail Laser Cast .429), 1,665fps @ 17,915psi

22gr with 200gr Winchester JSP (.426), 1,386fps @ 12,035psi

25.5gr with 200gr Winchester JSP, 1,735fps @ 19,652psi...this could exceed Winchester's published 22,000cup High Velocity loads. My guess is 18,000psi might be closer to 22,000cup.

26gr with 200gr lead "Magma" (Oregon Trail Laser Cast), 1,733fps @20,913psi...well beyond 22,000cup is my guess!!!

https://curtisshawk21.wixsite.com/44cen ... ss-powders

https://curtisshawk21.wixsite.com/44cen ... re-testing

-

Ray Newman

- Advanced Levergunner

- Posts: 2119

- Joined: Mon Dec 10, 2007 12:43 pm

- Location: Between No Where & No Place, WA

Re: 44 WCF with IMR 4227 or RL-7?

"I would try SR4759 or 5744. SR4759 was designed by Dupont as a low pressure smokless substitute for BP."

--LeftyDude

SR4759 is no longer in production. DuPont ceased SR4759 about 5-6 years ago.

--LeftyDude

SR4759 is no longer in production. DuPont ceased SR4759 about 5-6 years ago.

The most important aspect of this signature line is that you don't realize it doesn't say anything significant until you are just about done reading it & then it is too late to stop reading it....

Grand Poo Bah WA F.E.S.

In real life may you be the bad butt that you claim to be on social media.

Grand Poo Bah WA F.E.S.

In real life may you be the bad butt that you claim to be on social media.

Re: 44 WCF with IMR 4227 or RL-7?

And lefty wrote that 10 1/2 years ago......

-

Ray Newman

- Advanced Levergunner

- Posts: 2119

- Joined: Mon Dec 10, 2007 12:43 pm

- Location: Between No Where & No Place, WA

Re: 44 WCF with IMR 4227 or RL-7?

Ray: I posted that because I know of a few shooters in the last few years who tried to find SR4759. My post might save a Shooter some time trying to find an unobtainable powder.

The most important aspect of this signature line is that you don't realize it doesn't say anything significant until you are just about done reading it & then it is too late to stop reading it....

Grand Poo Bah WA F.E.S.

In real life may you be the bad butt that you claim to be on social media.

Grand Poo Bah WA F.E.S.

In real life may you be the bad butt that you claim to be on social media.

Re: 44 WCF with IMR 4227 or RL-7?

I hear you Ray......

Developing favorite loads only to find the powder discontinued is depressing and stocking-up before it's gone is ultimately just going to leave you with a lot of rusty, acrid fertilizer.

Developing favorite loads only to find the powder discontinued is depressing and stocking-up before it's gone is ultimately just going to leave you with a lot of rusty, acrid fertilizer.

-

missionary5155

- Levergunner 3.0

- Posts: 795

- Joined: Mon Feb 16, 2009 7:09 pm

- Location: Arequipa, Peru till 2020

Re: 44 WCF with IMR 4227 or RL-7?

Good morning

If this is the bullet you want to shoot why not shorten the brass to suit the crimp groove ? Then you can use any safe powder your heart desires.

Buy a box of Starline 44 WCF and go at it.

Yes I have done this and have no regrets. Unique , Greendot, Reddot and 20 other powders that fill the bill.

Mike in Peru

If this is the bullet you want to shoot why not shorten the brass to suit the crimp groove ? Then you can use any safe powder your heart desires.

Buy a box of Starline 44 WCF and go at it.

Yes I have done this and have no regrets. Unique , Greendot, Reddot and 20 other powders that fill the bill.

Mike in Peru

A sinner saved by FAITH in the Blood of Jesus Christ &teaching God´s Word in Peru. John 3:36

Tanker 71-74 NRA Life Ready to Defend the Constitution from enemies within and without.

Tanker 71-74 NRA Life Ready to Defend the Constitution from enemies within and without.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

After grouping 100 yard 4" groups and 265 yard 18" groups, I desiced to remove the scope from my Marlin 1894CB and revert back to open sights. I found some of those glasses with small holes and they work well. I did have to drill a small hole in the upper left corner for rifles and it works. I can see the open sights once more.

So for the first time in many years I shot open sights again. 100, 200 and 265 yards. First I had to "find" the target at 100 yards. It shoots a bit high and to the right. Easy adjustment BUT it got worse...lol

At 200 yards, I was using the bottom notch on the ladder sight. First shot was good but then I lost the target. I soon discovered that after each shot, the sight would bounce up the to second notch. Eventually I would just re-adjust after each shot. I left my tools home so a final adjustment was made after I got home, ready for the next trip.

Shooting the 265 yards war ridden gong, I was aiming low and to the left on the third notch....then I ran outta ammo......I started with 50 rounds so don't go counting how many hits were on target...lol

Grab some popcron and get ready to laugh!

https://youtu.be/zA1xba8dLZ0

So for the first time in many years I shot open sights again. 100, 200 and 265 yards. First I had to "find" the target at 100 yards. It shoots a bit high and to the right. Easy adjustment BUT it got worse...lol

At 200 yards, I was using the bottom notch on the ladder sight. First shot was good but then I lost the target. I soon discovered that after each shot, the sight would bounce up the to second notch. Eventually I would just re-adjust after each shot. I left my tools home so a final adjustment was made after I got home, ready for the next trip.

Shooting the 265 yards war ridden gong, I was aiming low and to the left on the third notch....then I ran outta ammo......I started with 50 rounds so don't go counting how many hits were on target...lol

Grab some popcron and get ready to laugh!

https://youtu.be/zA1xba8dLZ0

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

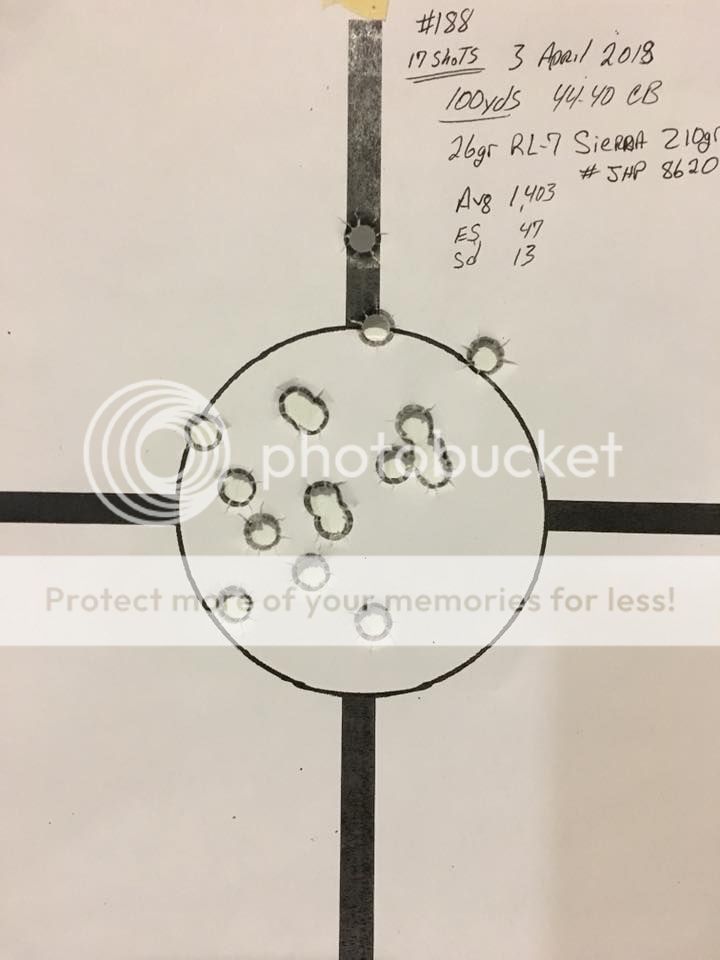

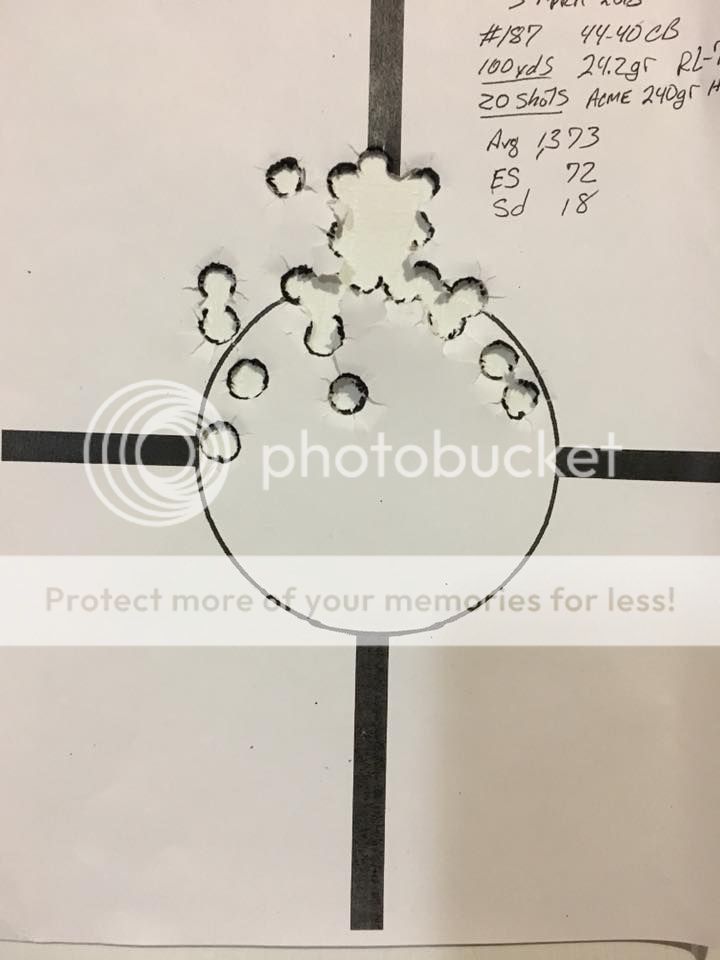

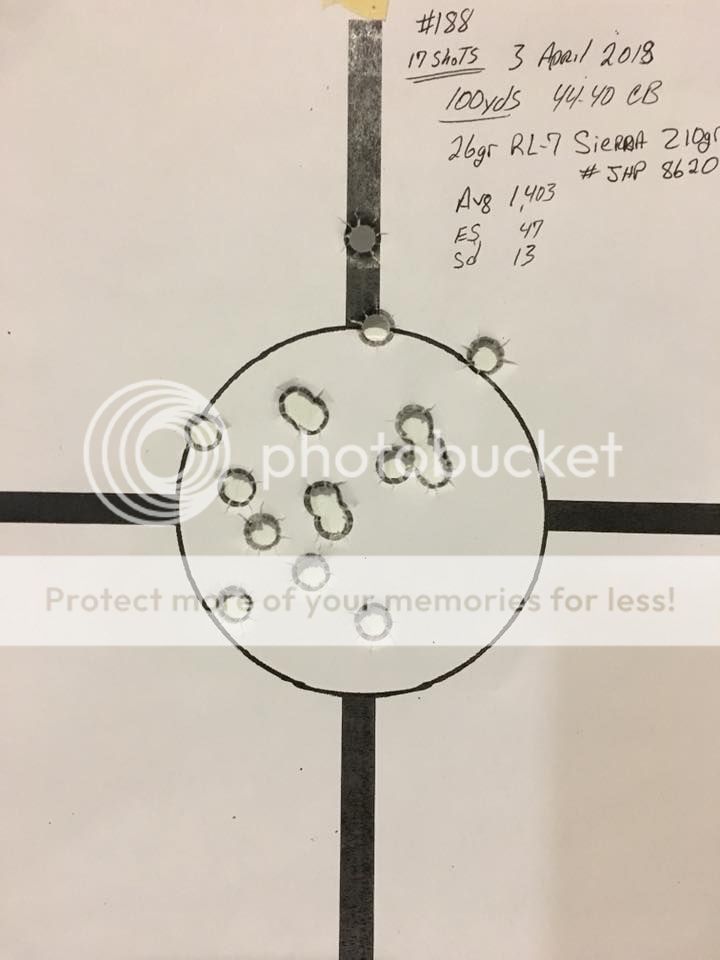

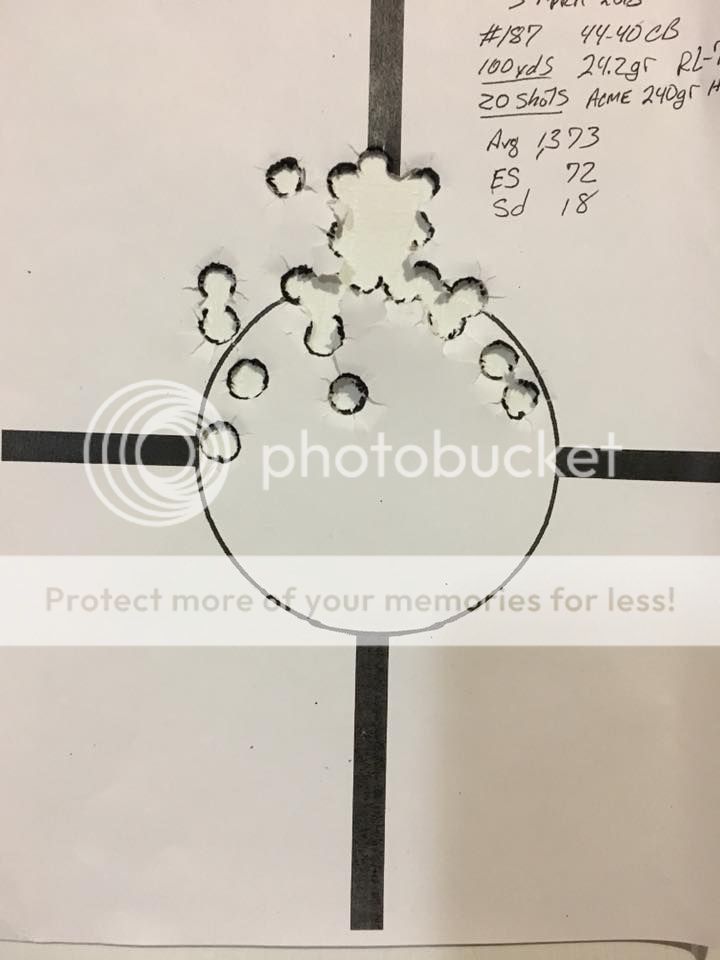

With all of that said and done, Reloder 7 gives similar results with less pressures and is excellent with 240gr bullets.

(PressuretraceII 13,000psi results) with my MGM testing barrel

(PressuretraceII 10,000psi results) with my MGM testing barrel

SAAMI MAX = 11,000psi/13,000cup

(PressuretraceII 13,000psi results) with my MGM testing barrel

(PressuretraceII 10,000psi results) with my MGM testing barrel

SAAMI MAX = 11,000psi/13,000cup

- otteray

- Levergunner 2.0

- Posts: 427

- Joined: Fri Mar 30, 2007 10:25 pm

- Location: Monterey Bay,CA and Tahoma, at Lake Tahoe CA

Re: 44 WCF with IMR 4227 or RL-7?

I still have 4 lbsRay Newman wrote: ↑Wed Mar 20, 2019 8:32 pm "I would try SR4759 or 5744. SR4759 was designed by Dupont as a low pressure smokless substitute for BP."

--LeftyDude

SR4759 is no longer in production. DuPont ceased SR4759 about 5-6 years ago.

otteray

Re: 44 WCF with IMR 4227 or RL-7?

Wow, 240 gr cast lead to 1373 fps from a 20" barrel at 10 ksi? Right impressive that. I imagine it leaves behind a mess of partly burned powder in the barrel. Is it sooty, too?

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

Everything I shoot is a mess....it's like a Jeep, either you love it or you hate it!

4227 burns "clean" but leaves particles just like all rifle powders....but is a tad sooty. Unique pistol powder is the dirtiest I have ever shot other than "Gunpowder".

Also, load data shows 23.5gr of Reloder 7 with a 240gr bullet @ 12,000cup. 12,000cup x .846 is 10,152psi. I would not recommend using that formula for anything outside of low pressures for the 44-40. SAAMI specifically publishes a max pressure of 11,000psi/13,000cup for the 44-40.

My results are taken directly from using the PressurtraceII, strain gauge system on a custom 1 1/4" dia. barrel.

4227 burns "clean" but leaves particles just like all rifle powders....but is a tad sooty. Unique pistol powder is the dirtiest I have ever shot other than "Gunpowder".

Also, load data shows 23.5gr of Reloder 7 with a 240gr bullet @ 12,000cup. 12,000cup x .846 is 10,152psi. I would not recommend using that formula for anything outside of low pressures for the 44-40. SAAMI specifically publishes a max pressure of 11,000psi/13,000cup for the 44-40.

My results are taken directly from using the PressurtraceII, strain gauge system on a custom 1 1/4" dia. barrel.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

https://curtisshawk21.wixsite.com/44cen ... re-testing

I also have 8 test videos on youtube.

https://www.youtube.com/watch?v=UN6undl ... az2I-xTMds

I also have 8 test videos on youtube.

https://www.youtube.com/watch?v=UN6undl ... az2I-xTMds

Re: 44 WCF with IMR 4227 or RL-7?

Yes, I had seen your page on pressure test results. It's quite useful information. I would add that I doubt 11,000 psi is the same as 13,000 CUP in the .44-40. In the .357, data shot to the CUP standard is generally faster than that shot to psi. This suggests the older CUP standard is actually higher pressure on average. Perhaps the piezo benches were showing excursions in pressure that development with CUP had never hinted at, and so they toned it down. Another aside: a 1-1/4" diameter test barrel is rather beefy for such a cartridge.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

Actually it is, or at least SAAMI say so on thier web site.

https://saami.org/wp-content/uploads/20 ... g-Copy.pdf

CUP page 21

PSI page 33

However, what that means is that particular group of test ammunition resulted in those numbers while being tested in the CUP equipment and Piezo equipment under thier 44-40 test ammunition standards.

Here are some "Standards" information from a third party source...

"44-40 pressures,

SAAMI barrels have minimum chambers and nominal bore dimensions. To mimic one, you have to get a barrel blank made to their bore cross-sectional area dimensions and then chamber it with a special reamer ground to produce the SAAMI minimum chamber diameters and not run it in past half a thousandth beyond what produces SAAMI minimum headspace. That's ±¼ of a thousandth, which can take some skill to do. Standard reamers are commonly made a little wider so they can be resharpened without losing dimensional precision. Denton Bramwell points out in the article [Link] most chambers made with standard reamers can expect to produce lower numbers.

SAAMI test barrels are fired with the cartridge manipulated to ensure the powder has fallen back over the flash hole. They are not tapped against anything to do this, as that packs the powder which can lower its burn rate a little. They want worst case highest pressure, so they just turn the case around to let the powder fall back to the rear, then load it carefully so as to avoid shifting the powder position. If you don't do that, you will get lower numbers than they do.

For rifle cartridges, SAAMI expects no more than 4% standard deviation in pressure. If your readings produce a higher SD than that, you are probably using a sample too small to be relied on to produce a good SD number. SAAMI uses ten rounds. Our own board member, Statshooter, who is a professor of statistics, says 30 rounds are needed. Denton Bramwell feels 15 rounds give him what he needs to know. So, why does SAAMI just use 10? They accept the SD results produced by 10 can be off on the high side by two standard errors (about another 2.5%), so they have a second number in addition to the MAP called the Maximum Probable Lot Mean, or MPLM, that allows the next sample of 10 from the same lot could produce a standard deviation that was different by that much. So, while the MAP is 11,000 psi, they allow they might get an average as high as 11,300 psi from another random sample of 10 from the same lot, and that is acceptable. They have a still higher number, called the Maximum Probable Sample Mean (MPSM) that allows that bullet bonding with the case and other factors can produce an increase in pressure as a lot of ammunition ages, and for the 44-40 that number is 11,700 psi. So, in effect, they are saying 11,700 psi is the safe limit, but, wait, there's more: All those numbers, the MAP, the MPLM, and the MPSM are averages produced by 10 round samples. The individual rounds making up that average will go above and below that average. SAAMI controls that by allowing what they call the Maximum Extreme Variation (MEV) which is the maximum spread between pressure readings for any of the 10 rounds in any sample taken at any time in the life of the lot. For the 44-40, the MEV is 2300 psi (this has to be calculated per the standard's instructions; it is not in a table). Theoretically, you could have aged loads centered on 11,700 psi whose 10 shots had one round as high as 13770 psi that would still be acceptable to SAAMI (though it is extremely improbable as it requires all 9 other shots to be exactly 11,470 psi). Mostly, though, you don't see individual rounds more than about ten percent above the MAP.

Even with all of that care, the fact is the absolute pressures are not exactly knowable. SAAMI reference cartridges are made in lots that are sent around to member's test facilities every two years to watch for reading changes. The members use SAAMI standard calibration methods (see the SAAMI standard) and report their results for both pressure and velocity from SAAMI standard test barrels. Interestingly, these vary more than the SAAMI standard deviation limit. The old 1992 standard gave an example for each method firing the same lots of reference loads, and the copper crushers, using targe tables for calibration, produced over 23% difference in average pressure for 10 shots among 9 labs. The transducers, using hydraulic pressure for calibration, produced over 11% difference in 10-shot averages among 7 labs. The reported results for each set of tests from each lab were, in turn, averaged and the final average was declared to be the pressure value that reference lot produced. This way, in effect, the reference lot pressure in the example was evaluated by looking at 90 and 70 total sample shots for the crusher and transducer, respectively. It compensates for average measurement calibration and operation errors, combined, to give a practical expected correct reading.

That approach may seem a bit tenuous, but understand the objective is to get everyone producing ammunition to the same standard, even if its absolute accuracy is not perfect. When a manufacturer wants to load a million rounds in a particular chambering, he buys a sample of a current lot of reference ammunition for that chambering and fires it in his own test equipment and compares his results to its agreed-upon rated pressure. This gives him a calibration factor for correcting his equipment's output to match the average output produced by the rest of the test labs that measured the lot. In the end, he doesn't load to the raw pressure readings his equipment provides, but to pressure readings corrected by what the reference load told him was his equipment's error factor.

So, if you wanted to compare strain gauge results to commercial equipment, one would ideally get some SAAMI reference ammunition to calibrate to. Unfortunately, reference ammunition is only sold to ammunition makers or others who can show a real need to have it. Otherwise, I think, they fear a run on it would occur that could interfere with the industry.

I notice all Hodgdon's psi-rated loads for the 44-40 exceed the SAAMI MAP, while their CUP-rated loads (in their pistol section) do not. Makes me wonder if someone confused the digits? It's still below the CIP's pressures, but those are measured on a different style of transducer (a channel transducer).

Regarding CUP ratings in manuals, while the correlation between CUP and psi is too poor for reliably converting one unit to the other over a range of chamberings, within a single chambering the conversion by the ratio of the CUP and psi maps within the SAAMI system is going to be close enough for practical work. That is, 11000 psi divided by 13000 CUP is 0.846 psi/CUP for the 44-40, so you can take the CUP numbers in the Lyman Manual and multiply them by 0.846 to get a reasonable expectation of psi. Conversely, dividing psi by that same number will come close to CUP." ~Uncklenick

https://saami.org/wp-content/uploads/20 ... g-Copy.pdf

CUP page 21

PSI page 33

However, what that means is that particular group of test ammunition resulted in those numbers while being tested in the CUP equipment and Piezo equipment under thier 44-40 test ammunition standards.

Here are some "Standards" information from a third party source...

"44-40 pressures,

SAAMI barrels have minimum chambers and nominal bore dimensions. To mimic one, you have to get a barrel blank made to their bore cross-sectional area dimensions and then chamber it with a special reamer ground to produce the SAAMI minimum chamber diameters and not run it in past half a thousandth beyond what produces SAAMI minimum headspace. That's ±¼ of a thousandth, which can take some skill to do. Standard reamers are commonly made a little wider so they can be resharpened without losing dimensional precision. Denton Bramwell points out in the article [Link] most chambers made with standard reamers can expect to produce lower numbers.

SAAMI test barrels are fired with the cartridge manipulated to ensure the powder has fallen back over the flash hole. They are not tapped against anything to do this, as that packs the powder which can lower its burn rate a little. They want worst case highest pressure, so they just turn the case around to let the powder fall back to the rear, then load it carefully so as to avoid shifting the powder position. If you don't do that, you will get lower numbers than they do.

For rifle cartridges, SAAMI expects no more than 4% standard deviation in pressure. If your readings produce a higher SD than that, you are probably using a sample too small to be relied on to produce a good SD number. SAAMI uses ten rounds. Our own board member, Statshooter, who is a professor of statistics, says 30 rounds are needed. Denton Bramwell feels 15 rounds give him what he needs to know. So, why does SAAMI just use 10? They accept the SD results produced by 10 can be off on the high side by two standard errors (about another 2.5%), so they have a second number in addition to the MAP called the Maximum Probable Lot Mean, or MPLM, that allows the next sample of 10 from the same lot could produce a standard deviation that was different by that much. So, while the MAP is 11,000 psi, they allow they might get an average as high as 11,300 psi from another random sample of 10 from the same lot, and that is acceptable. They have a still higher number, called the Maximum Probable Sample Mean (MPSM) that allows that bullet bonding with the case and other factors can produce an increase in pressure as a lot of ammunition ages, and for the 44-40 that number is 11,700 psi. So, in effect, they are saying 11,700 psi is the safe limit, but, wait, there's more: All those numbers, the MAP, the MPLM, and the MPSM are averages produced by 10 round samples. The individual rounds making up that average will go above and below that average. SAAMI controls that by allowing what they call the Maximum Extreme Variation (MEV) which is the maximum spread between pressure readings for any of the 10 rounds in any sample taken at any time in the life of the lot. For the 44-40, the MEV is 2300 psi (this has to be calculated per the standard's instructions; it is not in a table). Theoretically, you could have aged loads centered on 11,700 psi whose 10 shots had one round as high as 13770 psi that would still be acceptable to SAAMI (though it is extremely improbable as it requires all 9 other shots to be exactly 11,470 psi). Mostly, though, you don't see individual rounds more than about ten percent above the MAP.

Even with all of that care, the fact is the absolute pressures are not exactly knowable. SAAMI reference cartridges are made in lots that are sent around to member's test facilities every two years to watch for reading changes. The members use SAAMI standard calibration methods (see the SAAMI standard) and report their results for both pressure and velocity from SAAMI standard test barrels. Interestingly, these vary more than the SAAMI standard deviation limit. The old 1992 standard gave an example for each method firing the same lots of reference loads, and the copper crushers, using targe tables for calibration, produced over 23% difference in average pressure for 10 shots among 9 labs. The transducers, using hydraulic pressure for calibration, produced over 11% difference in 10-shot averages among 7 labs. The reported results for each set of tests from each lab were, in turn, averaged and the final average was declared to be the pressure value that reference lot produced. This way, in effect, the reference lot pressure in the example was evaluated by looking at 90 and 70 total sample shots for the crusher and transducer, respectively. It compensates for average measurement calibration and operation errors, combined, to give a practical expected correct reading.

That approach may seem a bit tenuous, but understand the objective is to get everyone producing ammunition to the same standard, even if its absolute accuracy is not perfect. When a manufacturer wants to load a million rounds in a particular chambering, he buys a sample of a current lot of reference ammunition for that chambering and fires it in his own test equipment and compares his results to its agreed-upon rated pressure. This gives him a calibration factor for correcting his equipment's output to match the average output produced by the rest of the test labs that measured the lot. In the end, he doesn't load to the raw pressure readings his equipment provides, but to pressure readings corrected by what the reference load told him was his equipment's error factor.

So, if you wanted to compare strain gauge results to commercial equipment, one would ideally get some SAAMI reference ammunition to calibrate to. Unfortunately, reference ammunition is only sold to ammunition makers or others who can show a real need to have it. Otherwise, I think, they fear a run on it would occur that could interfere with the industry.

I notice all Hodgdon's psi-rated loads for the 44-40 exceed the SAAMI MAP, while their CUP-rated loads (in their pistol section) do not. Makes me wonder if someone confused the digits? It's still below the CIP's pressures, but those are measured on a different style of transducer (a channel transducer).

Regarding CUP ratings in manuals, while the correlation between CUP and psi is too poor for reliably converting one unit to the other over a range of chamberings, within a single chambering the conversion by the ratio of the CUP and psi maps within the SAAMI system is going to be close enough for practical work. That is, 11000 psi divided by 13000 CUP is 0.846 psi/CUP for the 44-40, so you can take the CUP numbers in the Lyman Manual and multiply them by 0.846 to get a reasonable expectation of psi. Conversely, dividing psi by that same number will come close to CUP." ~Uncklenick

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

KWK, one thing I am still searching for is original, reliable CUP standards from 1873....this may be in reference to your reply right above mine. I failed to explain that...sorry

Re: 44 WCF with IMR 4227 or RL-7?

I have a copy of the 1992 book. I find only one example of testing reference loads, and that was with crushers. I see nothing in the 1992 book about firing a given lot of ammo in both types of pressure barrels, and, again, I'm not aware the pressure limits in psi and CUP were so set.The old 1992 standard gave an example for each method firing the same lots of reference loads, and the copper crushers, using tarage tables for calibration, produced over 23% difference in average pressure for 10 shots among 9 labs.

I don't think reference ammo is necessarily loaded to the limit pressure. It is certainly not used to establish the accuracy of the pressure measurement system. Rather, it appears to be used to verify a test set up is producing velocities and pressures in the range expected. It also can be used to see if a given set up is producing different pressures than it originally did.

Technically, there was none, for CUP is a postwar standard. Much goes into setting a pressure testing standard, including pressure sensor style, chamber and barrel cut, etc.I am still searching for is original, reliable CUP standards from 1873

Whelen's 1918 book said pressures ran 13,000 to 15,000 at that time. I don't have an older reference than that. Maybe some Winchester advertising will have listed the nominal pressure, but given the manufacturers back then were a bit optimistic in the fps claim, trusting a psi claim would be equally iffy. I suspect Winchester simply stuffed the case with BP and verified the action held up over a certain number of rounds.

Pressure testing started at least as early as 1861 in US Army labs, so just maybe Winchester did record and publish pressures.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

Great info!!!!!!

I would have to agree that the ammo is not tested to max which is why factory ammo is not max. It is my understanding (and there is a reason I do not gamble with money) that SAAMI sends (sells...whatever) out test ammo to manufactures for them to use as a "Control" for a lack of a better description.. The ammunition is manufactured to remain within "limits", regardless of accuracy. I can only guess if accuracy is not achieved while within those perimeters, the ammo is not manufactured.

In my correspondence with Buffalo Bore, I believe their manufacture of the 44-40 "Heavy" ammunition is right at max pressures (although data was not shared) while others like Winchester Super-X are manufactured up to 15% less than map pressures. Factory cowboy loads are nearly 50% less than max in my testings. Nearly the same actual results with reliable published hand-load data.

I would have to agree that the ammo is not tested to max which is why factory ammo is not max. It is my understanding (and there is a reason I do not gamble with money) that SAAMI sends (sells...whatever) out test ammo to manufactures for them to use as a "Control" for a lack of a better description.. The ammunition is manufactured to remain within "limits", regardless of accuracy. I can only guess if accuracy is not achieved while within those perimeters, the ammo is not manufactured.

In my correspondence with Buffalo Bore, I believe their manufacture of the 44-40 "Heavy" ammunition is right at max pressures (although data was not shared) while others like Winchester Super-X are manufactured up to 15% less than map pressures. Factory cowboy loads are nearly 50% less than max in my testings. Nearly the same actual results with reliable published hand-load data.

Re: 44 WCF with IMR 4227 or RL-7?

I believe the goal of reference ammo is consistency, not a particular pressure. It's performance is averaged over several firings in several (nominally) identical test set ups around the country. If it is suitably consistent, it is blessed as so.

If you look at the SAAMI documents, they describe taking pressures by using averages over several shots. They do not use reference ammo to calibrate the system, but the 1992 document (didn't check the 2015) says using a small offset calculated from reference ammo firing is optional when using crushers. Piezo systems are calibrated with hydraulic pressures.

Reference ammo only tells a lab if the entire set up is reasonable. It does not pinpoint what creates the error. If reference firings don't produce the expected pressure and velocity, you have to locate the cause. It could be the sensors, the chamber, the throat, the barrel, etc.

In your case, I'd use the Buffalo Bore stuff to establish a maximum tolerable indicated strain from your PressureTrace. It's a reasonable check, kind of your own personal reference ammo. In principle, through, the PressureTrace needs no calibration. One can calculate pressures from strain using basic materials engineering. If I recall, Denton Bramwell believes the system is more accurate than piezo systems.

If you look at the SAAMI documents, they describe taking pressures by using averages over several shots. They do not use reference ammo to calibrate the system, but the 1992 document (didn't check the 2015) says using a small offset calculated from reference ammo firing is optional when using crushers. Piezo systems are calibrated with hydraulic pressures.

Reference ammo only tells a lab if the entire set up is reasonable. It does not pinpoint what creates the error. If reference firings don't produce the expected pressure and velocity, you have to locate the cause. It could be the sensors, the chamber, the throat, the barrel, etc.

In your case, I'd use the Buffalo Bore stuff to establish a maximum tolerable indicated strain from your PressureTrace. It's a reasonable check, kind of your own personal reference ammo. In principle, through, the PressureTrace needs no calibration. One can calculate pressures from strain using basic materials engineering. If I recall, Denton Bramwell believes the system is more accurate than piezo systems.

Re: 44 WCF with IMR 4227 or RL-7?

SAAMI is a voluntary industry agreement. No maker is required to use its standards. In Europe there is a different set of standards, and I believe all the national labs there by law conform to it. With their piezo setup they limit the .44-40 to about 16,000 psi. SAAMI is 11,000. With crushers the psi are 13,000 (SAAMI) and 15,000 (CIP), but I think CIP no longer supports crusher readings.SAVVY_JACK wrote: ↑Sat Mar 23, 2019 2:07 pm... while others like Winchester Super-X are manufactured up to 15% less than map pressures.

Why the differences? Differences in chamber and throat cuts may occur in the translation of dimensions from inches to mm. The piezo sensor is used differently at CIP, as were the crushers. There is also a difference in the definition of MAP and how to average for it.

In the US, each cartridge maker looks at the market of old guns and sets their own limit for pressure. Few if any will load beyond SAAMI. This is probably the same under CIP. No one is required to load ammo to the limits.

I have a rolling block in .30-40. I personally will not load it with SAAMI spec ammo. I think that is too hot for the action. I fire only handloads to the sporting ammo velocities of the day, which is lower than SAAMI. I believe the SAAMI spec was based on prewar standards set using the hotter military ammo, the stuff which cracked some service bolt actions. Other examples of this are the .32-40 for which SAAMI has a pressure rating that Whelen puts in the High Velocity loading range, not the BP range. I wouldn't use full SAAMI pressures in a Ballard!

Loading to SAAMI pressure limits does not guarantee safety. I believe all SAAMI pressure ratings were reasonable in some production rifle but not necessarily all of them.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

Correct...KWK wrote: ↑Sat Mar 23, 2019 3:37 pmSAAMI is a voluntary industry agreement. No maker is required to use its standards. In Europe there is a different set of standards, and I believe all the national labs there by law conform to it. With their piezo setup they limit the .44-40 to about 16,000 psi. SAAMI is 11,000. With crushers the psi are 13,000 (SAAMI) and 15,000 (CIP), but I think CIP no longer supports crusher readings.SAVVY_JACK wrote: ↑Sat Mar 23, 2019 2:07 pm... while others like Winchester Super-X are manufactured up to 15% less than map pressures.

Why the differences? Differences in chamber and throat cuts may occur in the translation of dimensions from inches to mm. The piezo sensor is used differently at CIP, as were the crushers. There is also a difference in the definition of MAP and how to average for it.

In the US, each cartridge maker looks at the market of old guns and sets their own personal limit for pressure. Few if any will load beyond SAAMI.

Loading to SAAMI pressure limits does not guarantee safety. I believe all SAAMI pressure ratings were reasonable in some production rifle but not necessarily all of them.

...and CIP is what I used to use...all of that information is on my website. I also will certainly agree that manufactures liability issues limit themselves to below SAAMI recommendations. Some manufactures obviously do not. Buffalo Bore being one of them. Hot loads for the 45 Colt, 44 Magnum, and the 45-70 to name a few...the 44-40 is no different. There are not many 45-70 Trapdoor Springfields out there but we all know the MAP for the Springfield is lower than most modern 45-70 manufactured ammunition.

I really would like to dig in much further but I just waited too late in life...gotta keep saving for the retirement someday!!

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

KWK....can you post dates as to the development of the pressure testing methods? My brain is hurting!

Re: 44 WCF with IMR 4227 or RL-7?

I don't have years for all the methods; sorry.

The US Ordnance Dept was using a system in 1861 in which the piston drove a knife edge into a copper plate; Rodman was the name I think. About the same time, Nobel in Europe developed the crusher similar to that used today. Both systems have the piston mounted radially to the case wall.

In the UK, they used tubular crushers at the base of the case; I don't know the year of introduction.

Piezo development began around WW-I, and at the same time there was a photographic method (using a deflected light beam) to record pressure traces.

SAAMI formed after WW-I and came up with a standardized testing method with crushers. Some time after WW-II, the "CUP" system was created; I do not know how different were the pre and post war standards in implementation (if at all).

Strain gauges were first, I think, used more like a piezo system, with a radial tap for a transducer squeezed by the piston. Then came the idea of placing the gauge on the barrel over the chamber. I don't know when either were introduced.

I see there's a book which covers the subject at the U.Illinois library, where my son is. I'll try to borrow it.

The US Ordnance Dept was using a system in 1861 in which the piston drove a knife edge into a copper plate; Rodman was the name I think. About the same time, Nobel in Europe developed the crusher similar to that used today. Both systems have the piston mounted radially to the case wall.

In the UK, they used tubular crushers at the base of the case; I don't know the year of introduction.

Piezo development began around WW-I, and at the same time there was a photographic method (using a deflected light beam) to record pressure traces.

SAAMI formed after WW-I and came up with a standardized testing method with crushers. Some time after WW-II, the "CUP" system was created; I do not know how different were the pre and post war standards in implementation (if at all).

Strain gauges were first, I think, used more like a piezo system, with a radial tap for a transducer squeezed by the piston. Then came the idea of placing the gauge on the barrel over the chamber. I don't know when either were introduced.

I see there's a book which covers the subject at the U.Illinois library, where my son is. I'll try to borrow it.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

Great information, thanks!KWK wrote: ↑Sat Mar 23, 2019 11:44 pm I don't have years for all the methods; sorry.

The US Ordnance Dept was using a system in 1861 in which the piston drove a knife edge into a copper plate; Rodman was the name I think. About the same time, Nobel in Europe developed the crusher similar to that used today. Both systems have the piston mounted radially to the case wall.

In the UK, they used tubular crushers at the base of the case; I don't know the year of introduction.

Piezo development began around WW-I, and at the same time there was a photographic method (using a deflected light beam) to record pressure traces.

SAAMI formed after WW-I and came up with a standardized testing method with crushers. Some time after WW-II, the "CUP" system was created; I do not know how different were the pre and post war standards in implementation (if at all).

Strain gauges were first, I think, used more like a piezo system, with a radial tap for a transducer squeezed by the piston. Then came the idea of placing the gauge on the barrel over the chamber. I don't know when either were introduced.

I see there's a book which covers the subject at the U.Illinois library, where my son is. I'll try to borrow it.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

Nice! I had thought of looking for Ordnance reports from that era but decided to fetch from the UIUC Library another book which google had located. I’ve read Ordnance reports from the 1890s when looking for information on the development of the .30-40, the cartridge for my rolling block.

I wonder if Ordnance evaluated the 1873. If so they might have recorded the pressures.

I wonder if Ordnance evaluated the 1873. If so they might have recorded the pressures.

- Bryan Austin

- Levergunner 2.0

- Posts: 454

- Joined: Sat Jan 08, 2011 6:05 pm

- Contact:

Re: 44 WCF with IMR 4227 or RL-7?

This could be a starting place, looks interesting!!

https://play.google.com/books/reader?id ... g=GBS.PA28

https://play.google.com/books/reader?id ... g=GBS.PA28