Difference with gilding and pure copper jackets?

Forum rules

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

- Canuck Bob

- Senior Levergunner

- Posts: 1830

- Joined: Sun Oct 11, 2009 11:57 am

- Location: Calgary, Canada

Difference with gilding and pure copper jackets?

I'm just looking for an education regarding these two jacket materials. I've noticed some premium bullet makers use copper while most use gilding metal jackets which I understand is copper plus some zinc. What are the advantages and disadvantages of each type?

- Old Savage

- Posting leader...

- Posts: 16962

- Joined: Mon Sep 03, 2007 3:43 pm

- Location: Southern California

Re: Difference with gilding and pure copper jackets?

It can apply to both an alloy and a coating - but in this use it is an alloy with about 5% zinc to the copper.

My impression is that gilding metal leaves less in the barrel but that really depends on the barrel I think.

My impression is that gilding metal leaves less in the barrel but that really depends on the barrel I think.

Re: Difference with gilding and pure copper jackets?

pure guess on my part. I think gilding metal is a little softer but more predictable. So, bullet makers can score the gilding metal where needed to assure more reliable expansion when compared to alloys with more pure copper.

-

new pig hunter

- Senior Levergunner

- Posts: 1368

- Joined: Fri Sep 14, 2007 5:11 pm

- Location: SoCal

Re: Difference with gilding and pure copper jackets?

"Gilding metal differs from solid copper in that it is harder, tougher and does not foul or increase pressure the way solid copper bullets do."

reference: https://www.hornady.com/store/MonoFlex-Bullets

Cheers,

Carl

reference: https://www.hornady.com/store/MonoFlex-Bullets

Cheers,

Carl

Re: Difference with gilding and pure copper jackets?

What Carl said, and also gilding metal has a lower rate of work hardening than the copper-zinc alloys (brasses) with higher zinc content.

Some bullet jackets have nickel in the copper alloy and those "cupronickel" bullets are silver in color and highly corrosion resistant. Gilding metal largely replaced cupronickel for use in bullets to reduce bore fouling, but I don't know what the newer silver colored bullets are alloyed with as they don't look to me like cupronickel.

I'm not sure why pure copper is ever used other than for ease of manufacturing. I don't shoot them, but everyone I've talked to who has reports moderate to severe copper fouling with them.

I'd love to hear more.

Oly

Some bullet jackets have nickel in the copper alloy and those "cupronickel" bullets are silver in color and highly corrosion resistant. Gilding metal largely replaced cupronickel for use in bullets to reduce bore fouling, but I don't know what the newer silver colored bullets are alloyed with as they don't look to me like cupronickel.

I'm not sure why pure copper is ever used other than for ease of manufacturing. I don't shoot them, but everyone I've talked to who has reports moderate to severe copper fouling with them.

I'd love to hear more.

Oly

Re: Difference with gilding and pure copper jackets?

I need to look up the coefficient of sliding friction for each of them. Is Gilding Metal slicker or is Copper slicker?

D. Brian Casady

Quid Llatine Dictum Sit, Altum Viditur.

Advanced is being able to do the basics while your leg is on fire---Bill Jeans

Don't ever take a fence down until you know why it was put up---Robert Frost

Quid Llatine Dictum Sit, Altum Viditur.

Advanced is being able to do the basics while your leg is on fire---Bill Jeans

Don't ever take a fence down until you know why it was put up---Robert Frost

Re: Difference with gilding and pure copper jackets?

As I remember from "Hatchers Notebook", the government used Cupro-nickle jackets when they went from just lead to the new smokeless powders. They had a big problem with fouling from the jackets and had to use strong ammonia solutions to clean it out of the barrel. Experiments showed adding tin to the jackets (copper) removed the fouling. At first metallic tin was added to the powder and helped but not the best choice. When the commercial ammunition companies started going to non-corrosive priming they found it also did away with metal fouling in the barrels. I believe the original jacket gilding metal was copper and tin, eventually the use of tin was dropped it was found that zinc worked in this applications. Copper was too soft as it was made then and had big fouling problems as well. Of course I may be wrong on all of this, have to dig out my copy of Hatchers book. ATB

-

new pig hunter

- Senior Levergunner

- Posts: 1368

- Joined: Fri Sep 14, 2007 5:11 pm

- Location: SoCal

Re: Difference with gilding and pure copper jackets?

"coefficient of sliding friction" ...... now there's an inexact science. So many variables: force, dry sliding, lubed sliding, velocity, oxide film .....

Here's a website:

1) the very top section discusses sliding friction, "Factors ....."

2) about halfway down is a big section of tabulated values, "Coefficients Of Friction"

http://www.roymech.co.uk/Useful_Tables/ ... _frict.htm

Cheers,

Carl

Here's a website:

1) the very top section discusses sliding friction, "Factors ....."

2) about halfway down is a big section of tabulated values, "Coefficients Of Friction"

http://www.roymech.co.uk/Useful_Tables/ ... _frict.htm

Cheers,

Carl

Re: Difference with gilding and pure copper jackets?

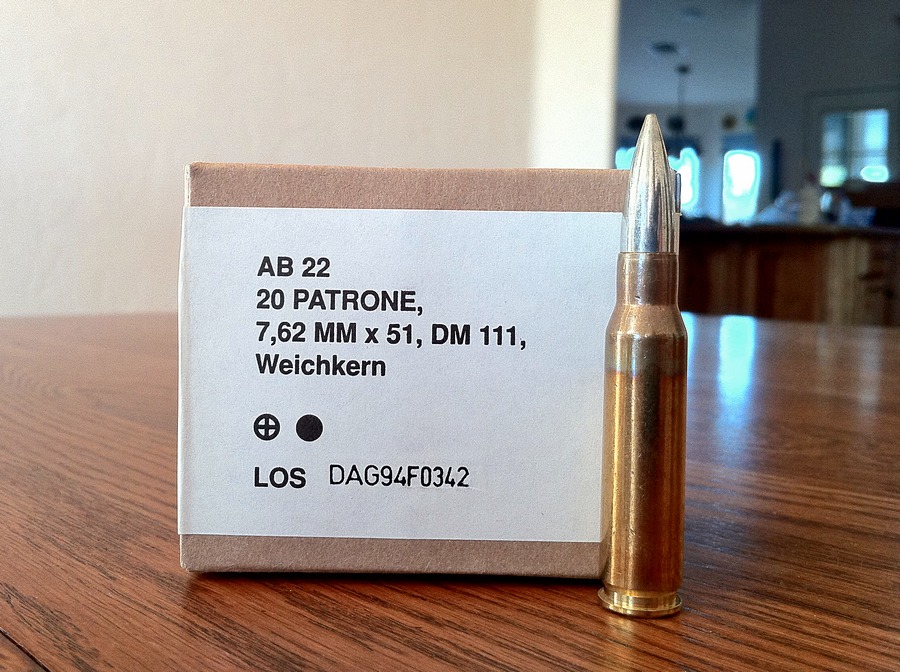

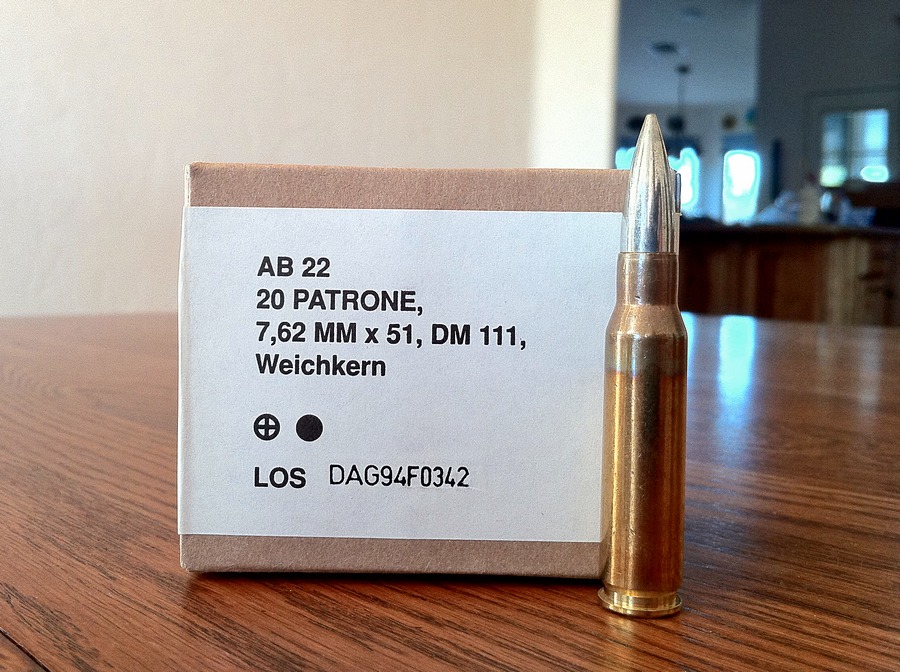

This German 7.62 NATO stuff uses cupronickel FMJs. It shoots great and was wonderfully priced but yep - it copper fouls the bore much more than U.S. ammo.

Oly

Oly