Excellent explanation Buck. Even I followed along.

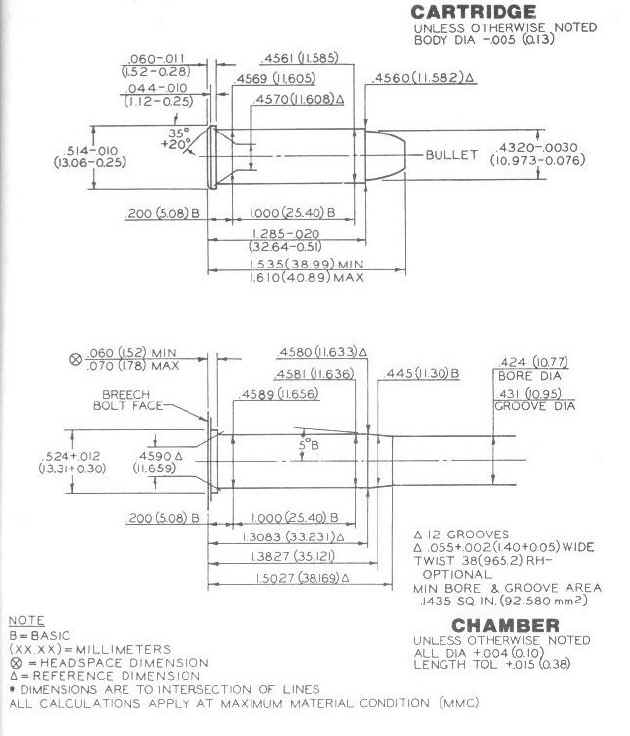

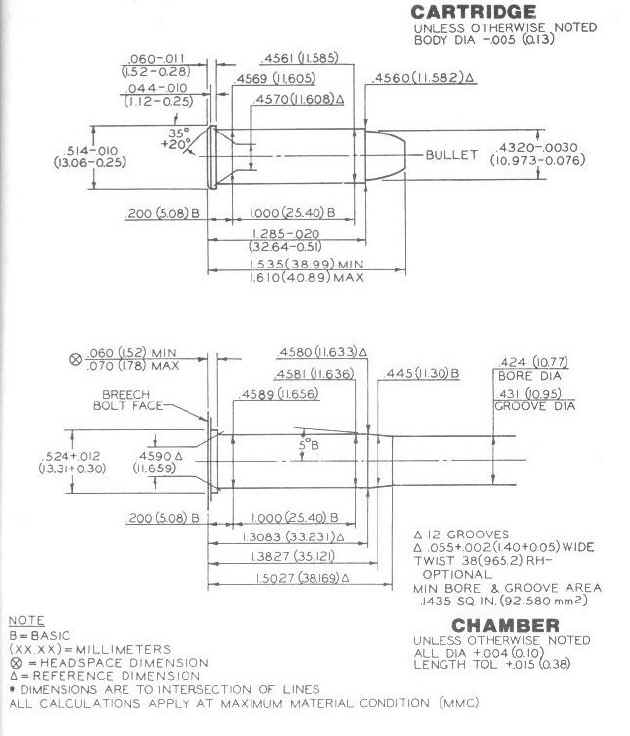

Now, for the bad news; both the chamber and your brass have manufacturing tolerances. Lets continue with the .44 Mag Doc is interested in. SAAMI sez that for the chamber to be "in spec", the relief for the cartridge rim must be between 0.060"-0.070". Likewise SAAMI sez the cartridge rim should be 0.060"-0.011

So, unless I'm mis-reading something, you could have a max chamber of 0.070" and if your brass rims were runnin' right @ 0.060", you'd be exceeding the .003-.007" headspace most recommend, yet be "in-spec". 'Tis why I prefer the Plasti-gage method of checking headspace over "go-no-go" gages for rifles. For revolvers, I don't know any other method. I can measure the rim thickness of my brass, add the squashed plasti-gage dimension and know immediately what the actual dimension my brass must be to keep my headspace within the recommended range.

Now, do I do that? Not ALL the time, but do whenever I get a new bunch of brass... With my .45 Colts, not so much, as I'm runnin' those at light moderate velocities, less than 1,000fps outta a 24" barrel. But, my .30-30s, yep, I'll sample 50-75 cases out of a thousand. If those run pretty consistent, I'm good. When I've picked up range brass, I tend to be pickier. I prefer brass that was from new ammo, verifiable as "once fired".

Since most of my .30-30 shooting is done with one specific rifle, and it tends to split necks after the 3rd or 4th reload, I don't have to worry about too much about other indicators.