Hate to keep draging this back but some of you may want to see.

I found this pic in Lee`s site. They must have changed the way they are made. No wire ring (clip ) in it or noted in tha parts list.

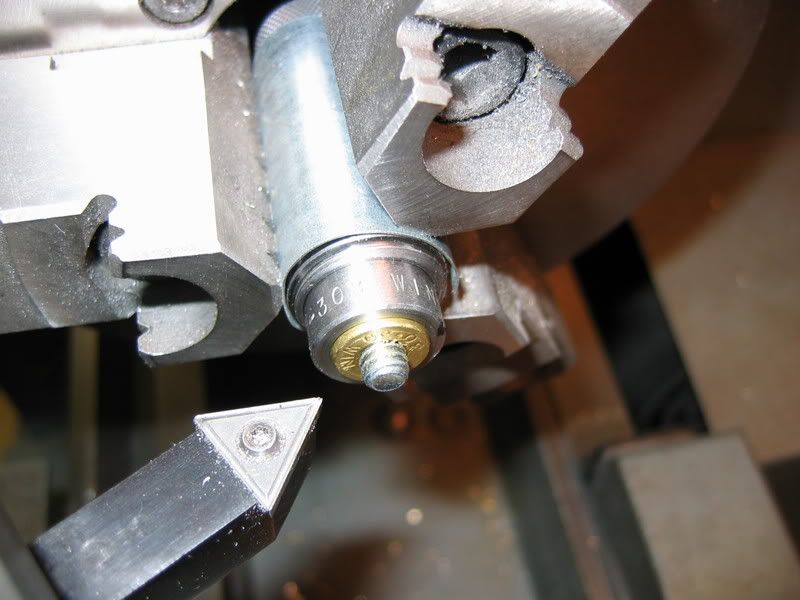

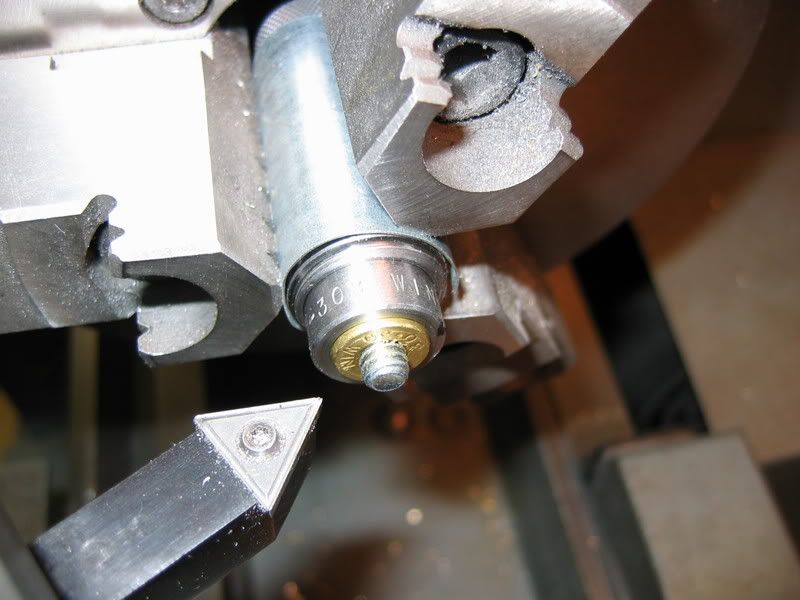

I found a .30-30 case will just catch the chamfered edge of the collet and extend through the collets jaws, thus it is held centered in the collet. I drilled out and threaded the primer hole to 1/4 x20 tpi in my lathe.

A 1/4" draw bolt and flat washer holds the collet tight in the die body`s taper.

All that is left is to turn .175 from the base of the collet.

I made up a dummy round this morning and find it works GREAT.

Lee`s site does say that if you are using the NEW Lee seating die that little is gained by using the rifle FCD due to the modified taper crimp that is used in the new Lee rifle dies.

I use a Lyman M-die to flair and expand the case mouth for cast bullets and just wanted to remove that flair. This modified Lee FCD does this well.

Some will say, just run the loaded round back part way into the full length sizing die to accomplish the same thing. Well, It takes me longer to remove the decaping stem and readjust it again than it does to use the FCD and also making things in my lathe is fun!!