OT - Way OT, not even in the ball park. I need a fan part

Forum rules

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

- J Miller

- Member Emeritus

- Posts: 14906

- Joined: Sat Mar 31, 2007 7:46 pm

- Location: Not in IL no more ... :)

OT - Way OT, not even in the ball park. I need a fan part

Very, Way OT, not even in the ball park. I need a fan part fabricated.

I have an old Westinghouse oscillating fan that works better than any of the new junk.

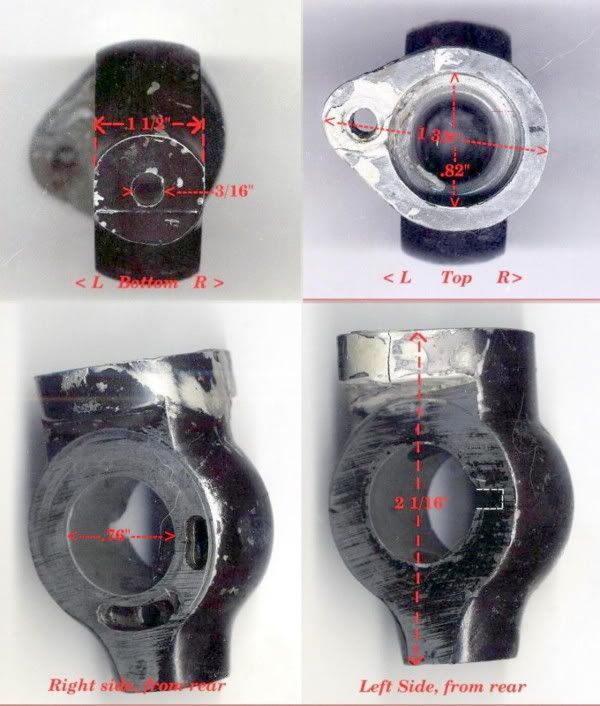

But the part that connects the base to the motor and the oscillator parts has broken. I've epoxied it once and it broke again.

This part is made from aluminum or pot metal or what I don't know. The fan is probably late teens early 20s manufacture. Yep, almost a 100 years old.

This part will require either a casting with clean up machining, or a complete machining job.

I have pictures of the part, and I can supply the original part as a sample.

Does anybody have any idea who could do this job?

Now, if somebody would know of any sources for antique fan parts, that would even be better.

Joe

I have an old Westinghouse oscillating fan that works better than any of the new junk.

But the part that connects the base to the motor and the oscillator parts has broken. I've epoxied it once and it broke again.

This part is made from aluminum or pot metal or what I don't know. The fan is probably late teens early 20s manufacture. Yep, almost a 100 years old.

This part will require either a casting with clean up machining, or a complete machining job.

I have pictures of the part, and I can supply the original part as a sample.

Does anybody have any idea who could do this job?

Now, if somebody would know of any sources for antique fan parts, that would even be better.

Joe

Just an idea. Contact Westinghouse with the model number etc (if you can find it,) they may have a part, or be willing to make one and use the story to show how well the product is made. You might want to try their marketing department. You never know unless you try. Good luck.

Happiness is a comfortable stump on a sunny south facing mountain.

I need a pic. I have several old Westinghouse fans.

Kind regards,

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

Joe, do you have a pic of the assembled fan? Or assembled enough for me to tell which one it is?

Kind regards,

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

Look on ebay for a pic of one like yours and post the link.

Kind regards,

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

- J Miller

- Member Emeritus

- Posts: 14906

- Joined: Sat Mar 31, 2007 7:46 pm

- Location: Not in IL no more ... :)

eBay??????????? Barfffffsss, gag, puke ............ OK, I'll check.

Tycer,

Here is the link to a fan of the exact style number as mine.

http://cgi.ebay.com/Vintage-Antique-Wes ... dZViewItem

The part I need , or one of them, is the part between the base and the motor.

If you'll look at the one pic that shows the back, then look down and see the big wing nut the part it goes into is what I need.

J e

e

Tycer,

Here is the link to a fan of the exact style number as mine.

http://cgi.ebay.com/Vintage-Antique-Wes ... dZViewItem

The part I need , or one of them, is the part between the base and the motor.

If you'll look at the one pic that shows the back, then look down and see the big wing nut the part it goes into is what I need.

J

I have one like that and it's cracked there too.

My thought was to drill and tap it and use hardened screws to hold it together. It was obviously not a great design as we now know of three that are cracked in the same spot.

My thought was to drill and tap it and use hardened screws to hold it together. It was obviously not a great design as we now know of three that are cracked in the same spot.

Kind regards,

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

Tycer

----------------------------------------------------------------

http://www.saf.org - https://peakprosperity.com/ - http://www.guntalk.com

- Rimfire McNutjob

- Advanced Levergunner

- Posts: 3388

- Joined: Mon Sep 03, 2007 2:51 pm

- Location: Sanford, FL.

- Rimfire McNutjob

- Advanced Levergunner

- Posts: 3388

- Joined: Mon Sep 03, 2007 2:51 pm

- Location: Sanford, FL.

If it's zinc alloy and I put the TIG torch to it ... it will vanish into a puff of white smoke and a molten silver pool. The zinc alloys have a pretty low melting point and zinc. If it's aluminum, it can be TIG'd. It could also be recast in 356 if you were to super-glue it together and use it as a pattern in the sand mold. It would still require some finish machining though.

- J Miller

- Member Emeritus

- Posts: 14906

- Joined: Sat Mar 31, 2007 7:46 pm

- Location: Not in IL no more ... :)

It is glued - epoxyed back together right now. I did that to get the pictures.

Someone PM'd me about manufacturing me a replacement part, but I don't know which member it is.

I probably should find out.

I don't think this part is aluminum. It more resembles the pot metal that was used before aluminum came out in the 30s. I really don't know though. It's a gray material that is very coarse where it fractured.

Joe

Someone PM'd me about manufacturing me a replacement part, but I don't know which member it is.

I probably should find out.

I don't think this part is aluminum. It more resembles the pot metal that was used before aluminum came out in the 30s. I really don't know though. It's a gray material that is very coarse where it fractured.

Joe